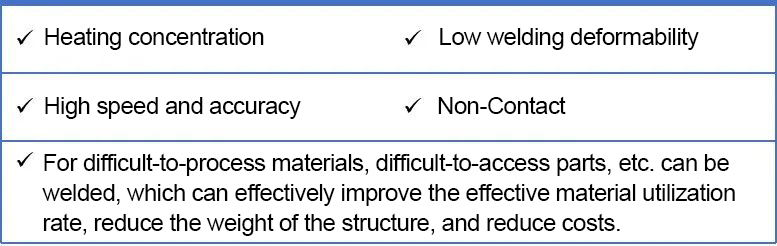

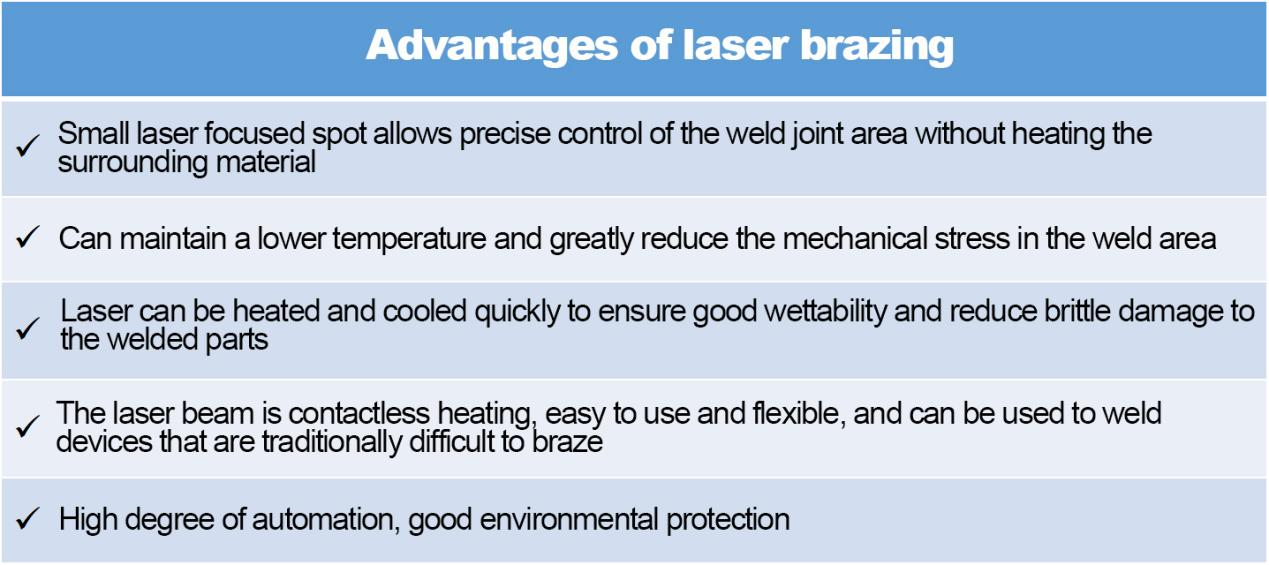

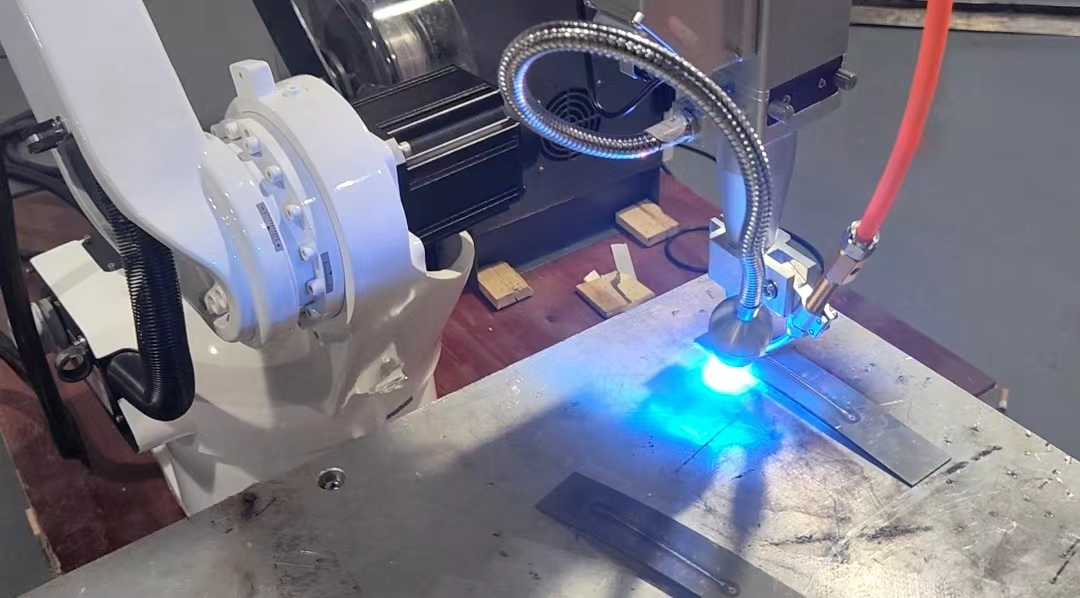

Teknụzụ na-ejikọta Laser, ma ọ bụ teknụzụ ịgbado ọkụ laser, na-eji ọkụ ọkụ laser dị elu na-elekwasị anya ma na-achịkwa irradiation nke elu ihe, na elu ihe ahụ na-amịkọrọ ike laser ma gbanwee ya n'ime ike ọkụ, na-eme ka ihe ahụ kpoo ọkụ ma gbazee. , na-esote jụrụ oyi na ihe siri ike iji nweta njikọ nke ihe ndị yiri ma ọ bụ ihe ndị yiri ya. Usoro ịgbado ọkụ laser chọrọ njupụta ike laser nke 104ruo 108W/cm2. Tụnyere usoro ịgbado ọkụ ọdịnala, ịgbado ọkụ laser nwere uru ndị a.

Teknụzụ na-ejikọta Laser, ma ọ bụ teknụzụ ịgbado ọkụ laser, na-eji ọkụ ọkụ laser dị elu na-elekwasị anya ma na-achịkwa irradiation nke elu ihe, na elu ihe ahụ na-amịkọrọ ike laser ma gbanwee ya n'ime ike ọkụ, na-eme ka ihe ahụ kpoo ọkụ ma gbazee. , na-esote jụrụ oyi na ihe siri ike iji nweta njikọ nke ihe ndị yiri ma ọ bụ ihe ndị yiri ya. Usoro ịgbado ọkụ laser chọrọ njupụta ike laser nke 104ruo 108W/cm2. Tụnyere usoro ịgbado ọkụ ọdịnala, ịgbado ọkụ laser nwere uru ndị a.

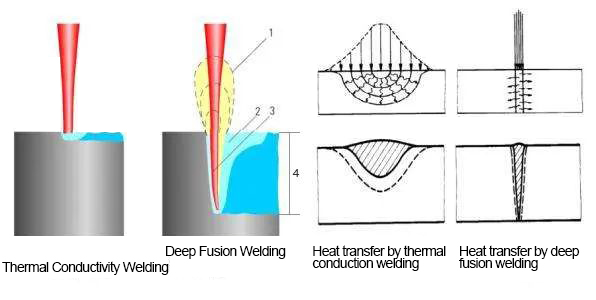

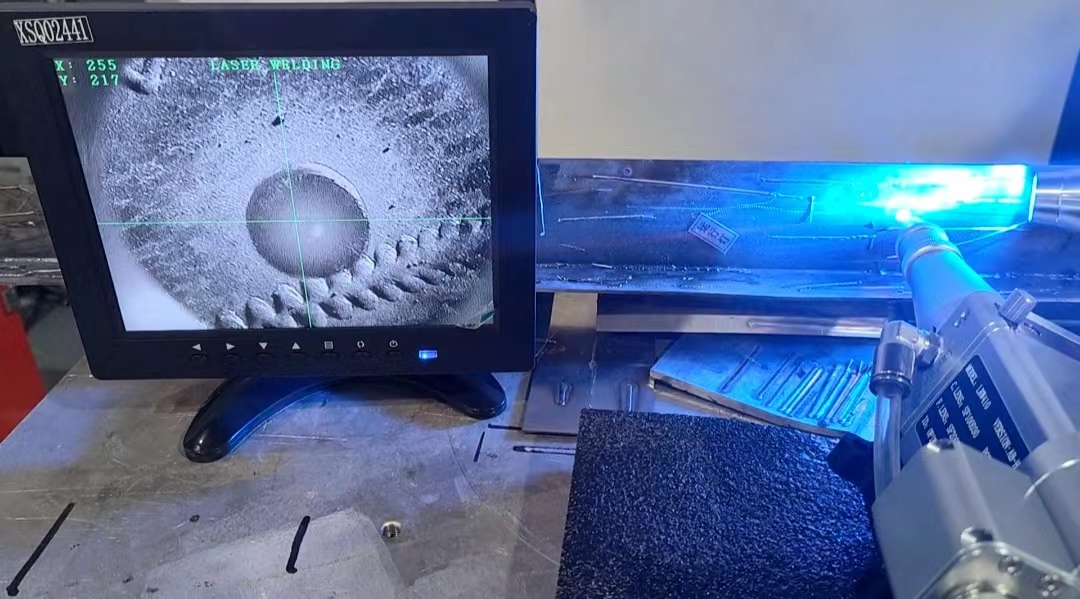

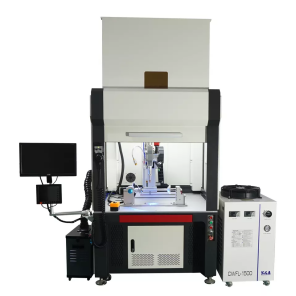

Igwe ojii 1-plasma, ihe na-agbaze 2, oghere igodo 3, omimi 4 nke ngwakọta

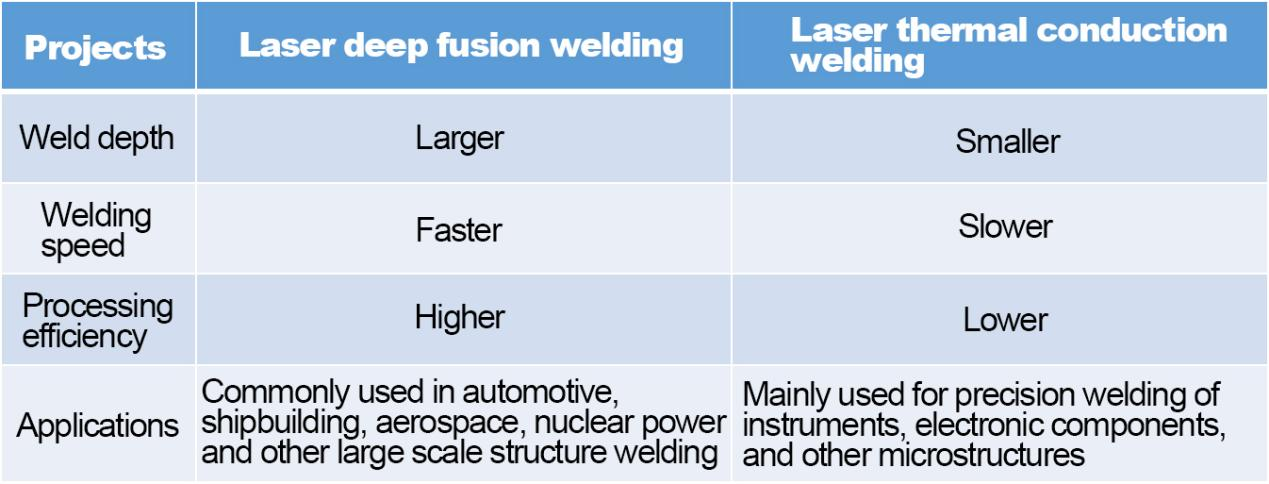

N'ihi ịdị adị nke igodo igodo ahụ, eriri laser ahụ, mgbe ọ gbasasịrị n'ime ime igodo ahụ, ga-eme ka mmịpụta nke laser site na ihe onwunwe ma kwalite nhazi nke ọdọ mmiri a wụrụ awụ mgbe ịgbasa na mmetụta ndị ọzọ, a na-atụnyere ụzọ ịgbado ọkụ abụọ ahụ. dị ka ndị a.

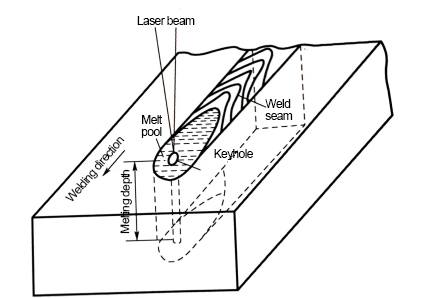

Ọnụ ọgụgụ dị n'elu na-enye usoro ịgbado ọkụ laser nke otu ihe ahụ na otu ọkụ ọkụ ahụ, usoro ntụgharị ike na-eme naanị site na isi ihe, igodo igodo na ígwè a wụrụ awụ dị nso na mgbidi nke oghere ahụ na-aga n'ihu nke laser doo, Igwe a wụrụ awụ na-eme ka oghere igodo ahụ pụọ n'ikuku nke fọdụrụ n'azụ iji mejupụta na mgbe condensation gasịrị, na-akpụ eriri weld.

Ọ bụrụ na ihe a ga-agbado bụ metal dị iche iche, ịdị adị nke ọdịiche dị na ihe ndị na-ekpo ọkụ ga-enwe mmetụta dị ukwuu na usoro ịgbado ọkụ, dị ka ọdịiche dị na ebe mgbaze, okpomọkụ conductivity, ikike okpomọkụ kpọmkwem, na mgbasawanye mgbasa nke ihe dị iche iche, na-akpata. na nrụgide ịgbado ọkụ, ịgbado ọkụ deformation, na mgbanwe na crystallization ọnọdụ nke welded nkwonkwo metal, na-eme ka mbelata n'ibu Njirimara nke weld.

Ya mere, dị ka àgwà dị iche iche nke ebe ịgbado ọkụ, usoro ịgbado ọkụ ewepụtala ịgbado ọkụ laser, brazing laser, igwe ịgbado ọkụ nke abụọ, ịgbado ọkụ laser mejupụtara, wdg.

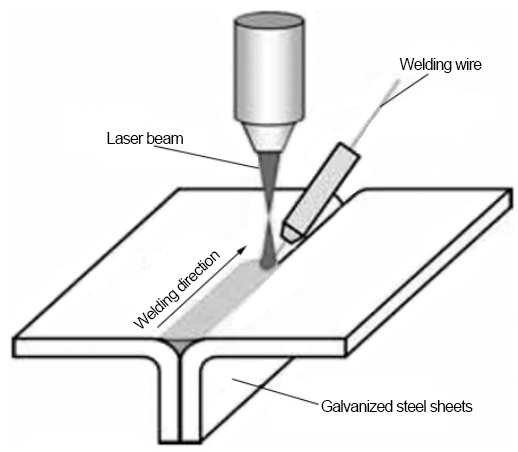

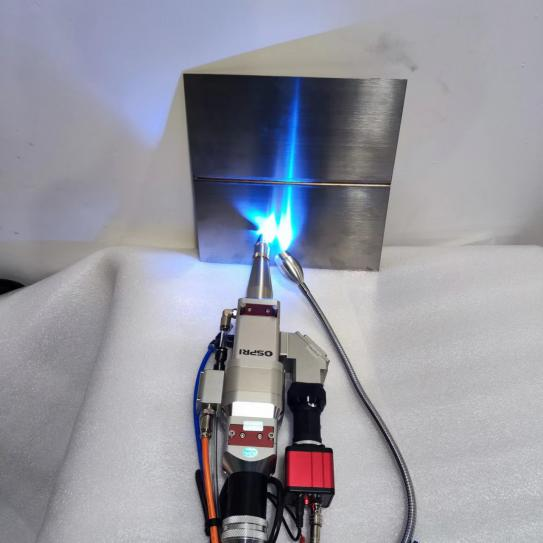

Ịgbado ọkụ na-ejuputa waya laser

Na laser ịgbado ọkụ usoro nke aluminum, titanium na ọla kọpa alloys, n'ihi na ala absorption nke laser ìhè (<10%) na ihe ndị a, foto emepụtara plasma nwere ụfọdụ ọta nke ìhè laser, ya mere ọ dị mfe na-etolite spatter na. na-eduga n'ọgbọ nke ntụpọ dị ka porosity na cracks. Ke adianade do, ịgbado ọkụ àgwà na-emetụta mgbe ọdịiche dị n'etiti workpieces bụ ibu karịa ntụpọ dayameta n'oge mkpa efere sputtering.

N'ịdozi nsogbu ndị a dị n'elu, enwere ike nweta nsonaazụ ịgbado ọkụ ka mma site na iji usoro ihe eji eme ihe. Ihe ndochi nwere ike ịbụ waya ma ọ bụ ntụ ntụ, ma ọ bụ enwere ike iji usoro ntinye ihe edoziri mbụ. N'ihi obere ebe a na-elekwasị anya, weld na-adịwanye warara ma nwee ọdịdị dị ntakịrị n'elu mgbe etinyere ihe mkpuchi.

Laser Brazing

N'adịghị ka welding welding, nke na-agbaze akụkụ abụọ welded n'otu oge, brazing na-agbakwụnye ihe na-ejuputa ihe nwere ebe mgbaze dị ala karịa ihe isi ala na elu weld, na-agbaze ihe mkpuchi ahụ iji mejupụta oghere ahụ na okpomọkụ dị ala karịa ihe mgbaze nke isi ihe. n'ókè na elu karịa ihe ndochi ihe si agbaze ebe, na mgbe ahụ condenses na-etolite a siri ike weld.

Brazing dabara adaba maka ngwaọrụ microelectronic nwere mmetụta okpomọkụ, efere dị gịrịgịrị, na ihe ọla na-agbanwe agbanwe.

Ọzọkwa, enwere ike kewaa ya dị ka brazing dị nro (<450 °C) na brazing siri ike (> 450 Celsius C) dabere na ọnọdụ okpomọkụ nke ihe mkpuchi ahụ na-ekpo ọkụ.

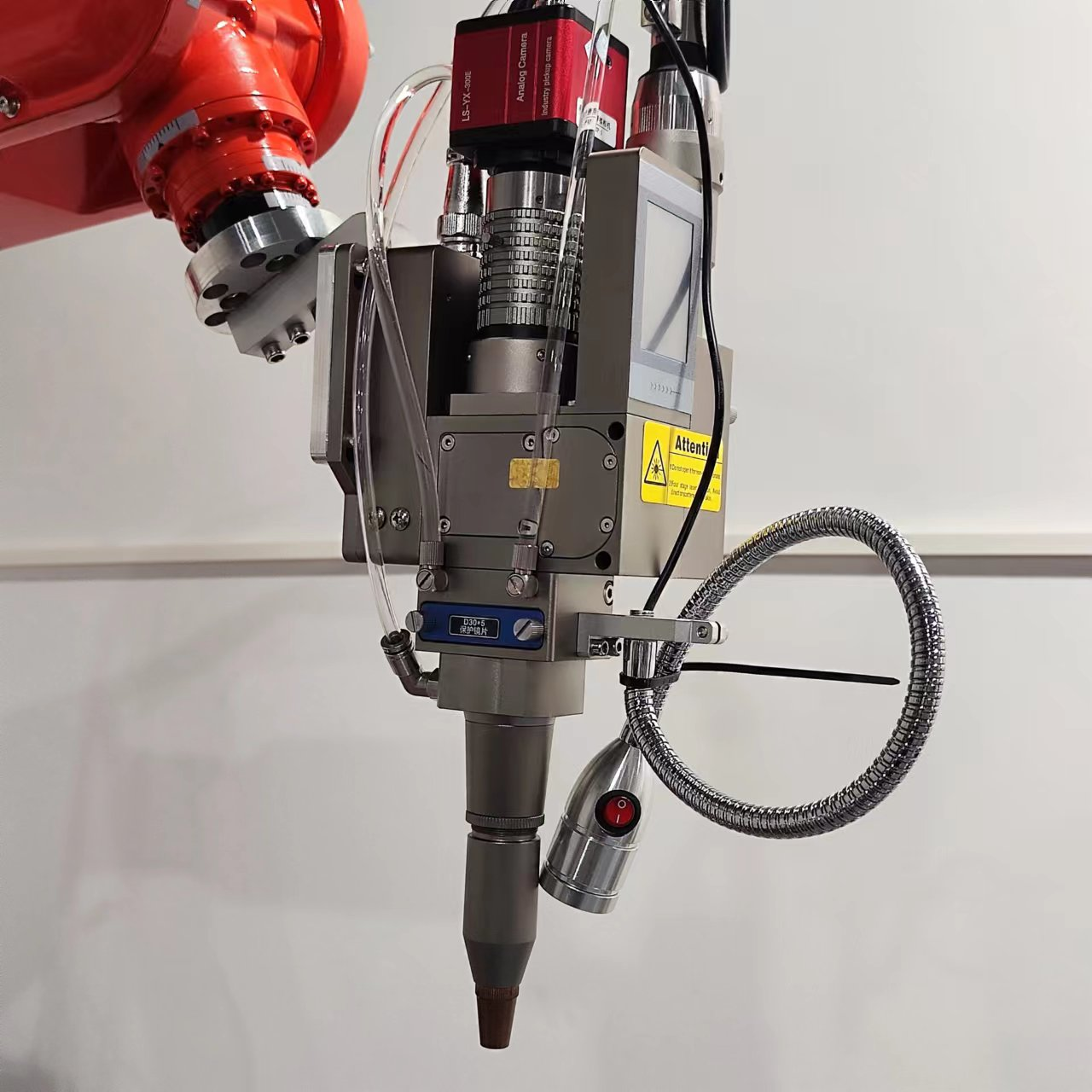

Igwe ọkụ Laser Dual Beam Welding

Ịgbado ọkụ abụọ-beam na-enye ohere ijikwa oge na ọnọdụ irradiation laser dị mfe ma dị mma, si otú a na-edozi nkesa ike.

A na-ejikarị ya maka ịgbado ọkụ laser nke aluminom na magnesium alloys, splice na ịgbado ọkụ n'apata maka ụgbọ ala, brazing laser na ịgbado ọkụ miri emi.

Enwere ike nweta eriri okpukpu abụọ site na lasers abụọ nọọrọ onwe ha ma ọ bụ site na nkewa ọkụ na nkewa ọkụ.

Igwe ọkụ abụọ ahụ nwere ike ịbụ ngwakọta nke lasers nwere njirimara ngalaba oge dị iche iche (pulsed vs. na-aga n'ihu), ogologo wavelengths dị iche iche (n'etiti infrared vs. anya na-ahụ anya) na ike dị iche iche, nke nwere ike ịhọrọ dịka ihe eji eme ihe n'ezie.

4.Laser Composite Welding

N'ihi na iji laser doo dị ka nanị okpomọkụ isi iyi, otu okpomọkụ isi iyi laser ịgbado ọkụ nwere obere ume mgbanwe ọnụego na itinye n'ọrụ ọnụego, weld isi ihe n'ọdụ ụgbọ mmiri interface dị mfe na-emepụta na-ezighị ezi, dị mfe na-emepụta pores na cracks na ndị ọzọ adịghị ike. iji dozie nsogbu a, ị nwere ike iji njirimara kpo oku nke isi ihe ndị ọzọ na-ekpo ọkụ iji meziwanye ikpo ọkụ nke laser na workpiece, nke a na-akpọkarị ịgbado ọkụ laser.

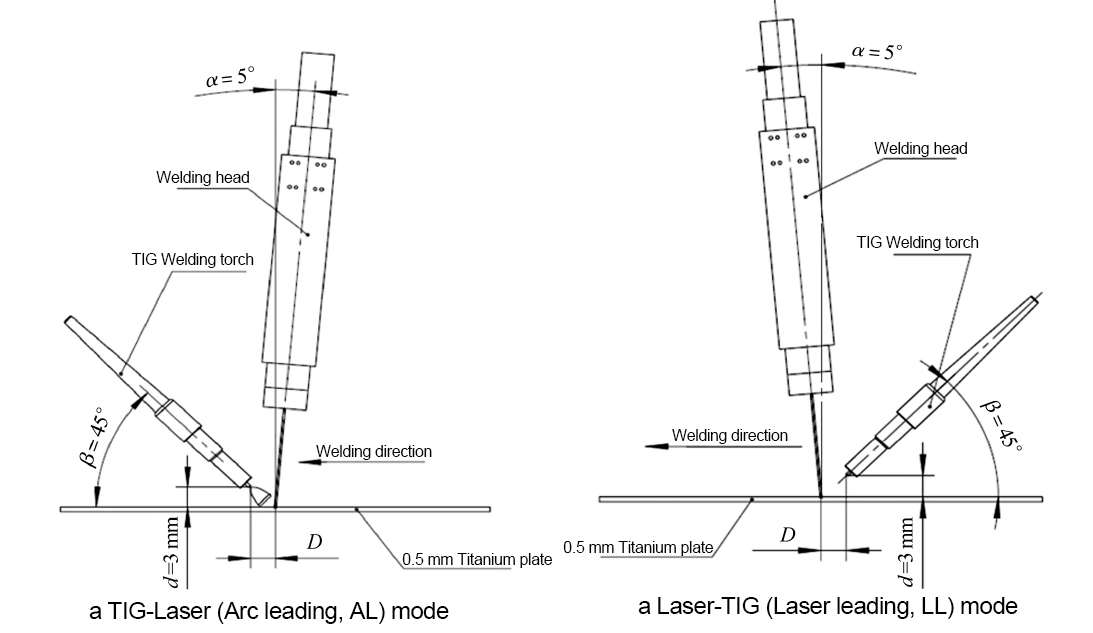

Ụdị isi nke ịgbado ọkụ nke laser mejupụtara bụ ịgbado ọkụ nke laser na arc eletrik, 1 + 1> 2 mmetụta dị ka ndị a.

mgbe eriri laser dị nso na arc etinyere,a na-ebelata njupụta elektrọn nke ukwuu, A na-agbaze igwe ojii plasma site na ịgbado ọkụ laser, nkenwere ike ime ka ọnụọgụ nnabata laser dịkwuo mma, ebe arc na isi ihe na-ekpo ọkụ ga-emewanyewanye ọnụego absorption nke laser.

2. elu ike itinye n'ọrụ nke arc na mkpokọtaA ga-abawanye itinye n'ọrụ ike.

3, mpaghara ịgbado ọkụ laser nke ime ihe dị ntakịrị, dị mfe ime ka enweghị isi nke ọdụ ụgbọ mmiri ịgbado ọkụ, ebe mmetụta ọkụ nke arc buru ibu, nke nwere ike.belata ihe na-ezighị ezi nke ọdụ ụgbọ mmiri. N'otu oge ahụ, ndịwelding àgwà na arụmọrụ nke arc na-mman'ihi na-elekwasị anya na-eduzi mmetụta nke laser doo na arc.

4, ịgbado ọkụ laser na elu elu okpomọkụ, nnukwu okpomọkụ emetụtara mpaghara, ngwa ngwa jụrụ na solidification ọsọ, mfe n'ịwa cracks na pores; ebe mpaghara okpomọkụ metụtara arc dị ntakịrị, nke nwere ike ibelata gradient okpomọkụ, jụrụ oyi, ọsọ ike siri ike,nwere ike belata ma kpochapụ ọgbọ nke pores na cracks.

E nwere ụdị abụọ a na-ahụkarị nke ịgbado ọkụ nke laser-arc: laser-TIG composite welding (dị ka egosiri n'okpuru) na laser-MIG mejupụtara ịgbado ọkụ.

Enwekwara ụdị ịgbado ọkụ ndị ọzọ dị ka laser na plasma arc, laser na inductive heat source compound.

Banyere MavenLaser

Maven Laser bụ onye ndu nke ngwa nrụpụta laser na China na onye na-enye ikike nke ngwọta nhazi laser zuru ụwa ọnụ. Anyị na-aghọta nke ọma mmepe na-emekarị nke n'ichepụta ụlọ ọrụ, mgbe niile na-eme ka anyị ngwaahịa na ngwọta, na-esi ọnwụ na-ịchọgharị mwekota nke akpaaka, informationization na ọgụgụ isi na n'ichepụta ụlọ ọrụ, na-enye laser ịgbado ọkụ akụrụngwa, Laser marking ngwá, Laser ihicha ngwá na laser gold na ọlaọcha ọla. ịcha ngwá ọrụ dị iche iche gụnyere zuru ike usoro, na nọgidere na-amụba anyị mmetụta na ubi nke laser ngwá.

Oge nzipu: Jan-13-2023