Dị ka onye na-ebu akụkụ ndị ọzọ nke ụgbọ ala ahụ, nkà na ụzụ mmepụta nke ụgbọ ala na-ekpebi kpọmkwem n'ichepụta àgwà nke ụgbọ ala ahụ. N'ime usoro mmepụta ahụ nke akpaaka, ịgbado ọkụ bụ usoro mmepụta dị mkpa. Teknụzụ ịgbado ọkụ nke a na-eji ugbu a maka ịgbado ọkụ ahụ akpaaka gụnyere ịgbado ọkụ na-eguzogide ntụpọ, ịgbado ọkụ inert gas na-echebe ịgbado ọkụ (MIG welding) na ịgbado ọkụ na-arụ ọrụ gas na-agbado ọkụ (MAG welding) yana ịgbado ọkụ laser.

Dị ka teknụzụ ịgbado ọkụ dị elu nke nwere ngwa anya-mechanical njikọ, teknụzụ ịgbado ọkụ laser nwere uru nke njupụta ume dị elu, ọsọ ịgbado ọkụ ngwa ngwa, nrụgide ịgbado ọkụ dị ala na nrụrụ, yana mgbanwe dị mma ma e jiri ya tụnyere teknụzụ ịgbado ọkụ nke akpaaka ọdịnala.

Ọdịdị ahụ ụgbọ ala dị mgbagwoju anya, akụkụ ahụ ya bụkwa ihe ndị nwere mgbidi na nke gbagọrọ agbagọ. Akpaaka ahụ ịgbado ọkụ na-eche ihu na ịgbado ọkụ ihe isi ike dị ka ọdịiche dị na ahụ ihe, dịgasị iche iche ọkpụrụkpụ nke akụkụ, iche iche ịgbado ọkụ trajectories na nkwonkwo ụdị. Na mgbakwunye, akpakanamde ahụ ịgbado ọkụ nwere nnukwu chọrọ na ịgbado ọkụ àgwà na ịgbado ọkụ arụmọrụ.

Dabere na usoro ịgbado ọkụ kwesịrị ekwesị, ịgbado ọkụ laser nwere ike hụ na ike ike ọgwụgwụ na mmetụta siri ike nke akụkụ ahụ akpaaka isi mgbe ịgbado ọkụ, si otú a na-ahụ maka ịdị mma na ndụ ọrụ nke ịgbado ọkụ ahụ. Teknụzụ ịgbado ọkụ laser nwere ike imeghari maka ịgbado ọkụ nke akụkụ ahụ akpaaka nwere ụdị nkwonkwo dị iche iche, ọkpụrụkpụ dị iche iche na ụdị ihe dị iche iche, na-egbo mkpa mgbanwe na nrụpụta ahụ. Ya mere, teknụzụ ịgbado ọkụ laser bụ ụzọ teknụzụ dị mkpa iji nweta mmepe dị elu nke ụlọ ọrụ ụgbọ ala.

Usoro ịgbado ọkụ laser maka ozu ụgbọ ala

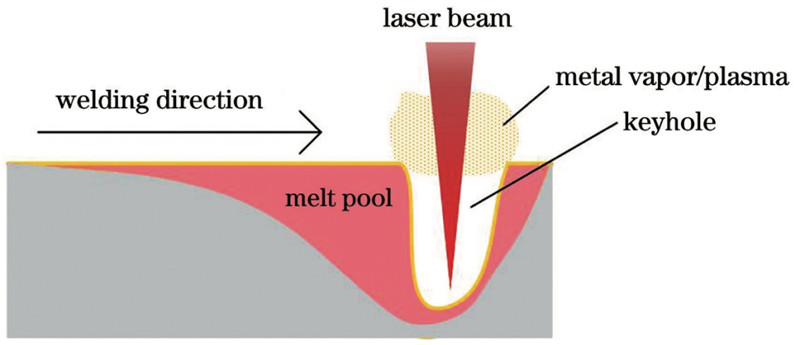

Usoro usoro ịgbado ọkụ laser miri emi: Mgbe njupụta ike laser ruru otu ọkwa, elu ihe ahụ na-eku ọkụ, si otú a na-akpụ isi. Mgbe uzuzu uzuoku n'ime oghere ahụ ruru nguzo siri ike na nrụgide static na nhụsianya elu nke mmiri mmiri gbara ya gburugburu, laser nwere ike ịgbanye site na igodo igodo ruo na ala oghere ahụ, site na mmegharị nke eriri laser, weld na-aga n'ihu bụ weld. kpụrụ. N'ime usoro ịgbado ọkụ laser miri emi, ọ dịghị mkpa ịgbakwunye flux inyeaka ma ọ bụ ihe ndochi iji weld ihe nke ya na-arụ ọrụ n'ime otu.

The weld seam nwetara site Laser miri welding ịgbado ọkụ na-adịkarị ire ụtọ na ogologo na obere nrụrụ, nke na-enyere aka melite n'ichepụta ziri ezi nke akpaaka ahu. Ike ike nke weld dị elu, nke na-eme ka ọ dị mma ịgbado ọkụ nke ahụ akpaaka. Ọsọ ịgbado ọkụ dị ngwa ngwa, nke na-enyere aka melite nrụpụta nrụpụta ịgbado ọkụ.

N'ime usoro ịgbado ọkụ nke akpaaka, iji usoro ịgbado ọkụ laser miri emi nwere ike belata ọnụ ọgụgụ akụkụ, ebu na ịgbado ọkụ, si otú a na-ebelata ibu ahụ nwụrụ anwụ na ụgwọ nrụpụta. Otú ọ dị, usoro ịgbado ọkụ laser miri emi adịghị anabata oghere mgbakọ nke akụkụ ndị a ga-agbado, yana mkpa ka a na-achịkwa oghere n'etiti 0.05 na 2 mm. Ọ bụrụ na oghere mgbakọ ahụ buru ibu, ntụpọ ịgbado ọkụ dị ka porosity ga-eme.

Nnyocha e mere ugbu a na-egosi na na ịgbado ọkụ na-arụ ọrụ nke otu ihe ahụ, site n'ịmepụta usoro paramita nke ịgbado ọkụ laser miri emi, ọ ga-ekwe omume ịnweta weld na nhazi elu dị mma, obere ntụpọ dị n'ime na ihe ndị dị mma. The magburu onwe n'ibu Njirimara nke weld nwere ike izute ojiji chọrọ nke akpaaka ahu welded components. Otú ọ dị, na akpaaka ahụ ịgbado ọkụ, aluminum alloy-steel dị ka ndị nnọchiteanya nke heterogeneous metal laser miri ịgbado ọkụ usoro adịghị tozuru okè, ọ bụ ezie na site na-agbakwụnye a mgbanwe oyi akwa nwere ike nweta magburu onwe arụmọrụ nke weld, ma dị iche iche mgbanwe oyi akwa ihe na. IMC Layer mmetụta usoro na mmetụta ya na micro Ọdịdị nke weld usoro bụ doro anya, mkpa ọzọ na-omimi ọmụmụ.

Usoro ịgbado ọkụ nke anụ ahụ Laser Wire

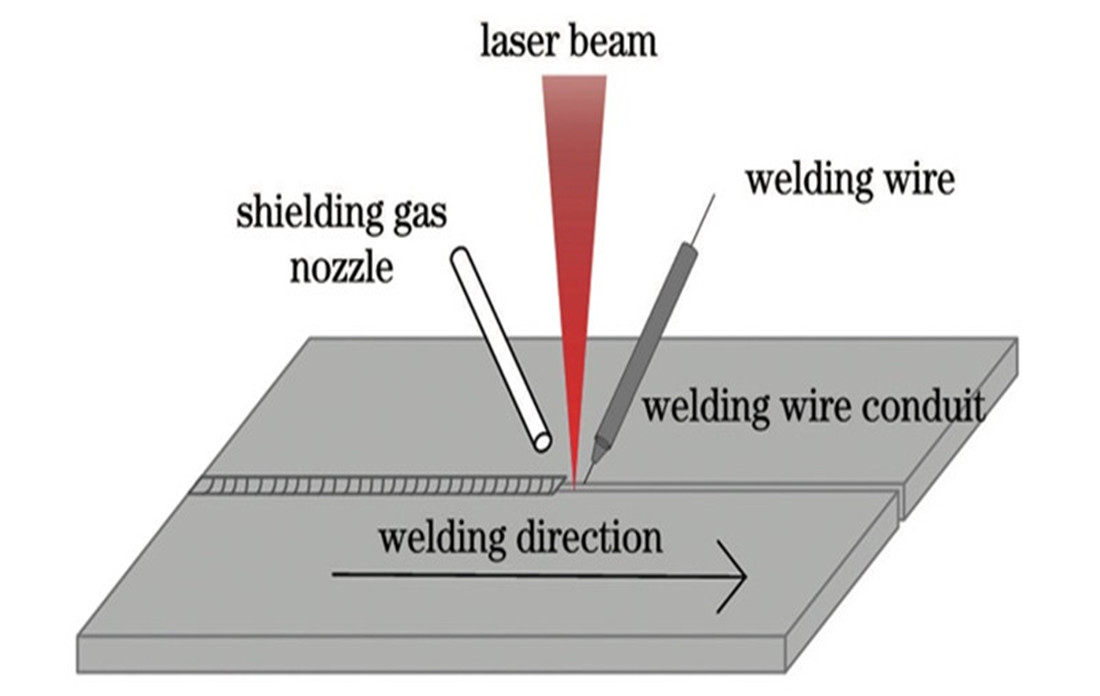

Usoro ịgbado ọkụ nke laser na-adabere n'ụkpụrụ ndị a: A na-emepụta njikọ nke welded site na iji otu waya emeju ihe nkedo ma ọ bụ site na ịnye waya n'otu oge n'oge usoro ịgbado ọkụ laser. Nke a bụ ihe na-eri nri ihe dị ka otu ọnụ ọgụgụ nke waya ihe n'ime weld ọdọ mmiri n'oge laser miri welding ịgbado ọkụ. Eserese dị n'okpuru na-egosi usoro ịgbado ọkụ laser.

E jiri ya tụnyere ịgbado ọkụ laser miri emi, ịgbado ọkụ laser nwere uru abụọ na ịgbado ọkụ akpaaka: nke mbụ, ọ nwere ike melite nnabata nke oghere ọgbakọ n'etiti akụkụ ahụ nke akpaaka ka a ga-agbado ma dozie nsogbu nke nnukwu oghere bevel chọrọ maka ịgbado ọkụ laser miri emi. ; Nke abuo, ọ nwere ike imeziwanye nkesa anụ ahụ na mpaghara weld site na iji wires nwere ọdịnaya dị iche iche mejupụtara, wee mezie ọrụ weld.

N'ime usoro mmepụta ahụ nke akpaaka, a na-ejikarị usoro ịgbado ọkụ laser iji weld alloy aluminum na nchara n'akụkụ ahụ. Karịsịa na usoro ịgbado ọkụ nke aluminum alloy akụkụ nke auto ahu, elu erughị ala nke a wụrụ awụ ọdọ mmiri bụ obere, nke nwere ike mfe iduga ọdịda nke a wụrụ awụ ọdọ mmiri, mgbe laser filler ịgbado ọkụ usoro nwere ike mma dozie nsogbu a wụrụ awụ ọdọ mmiri ida. site na agbaze nke waya na laser ịgbado ọkụ usoro.

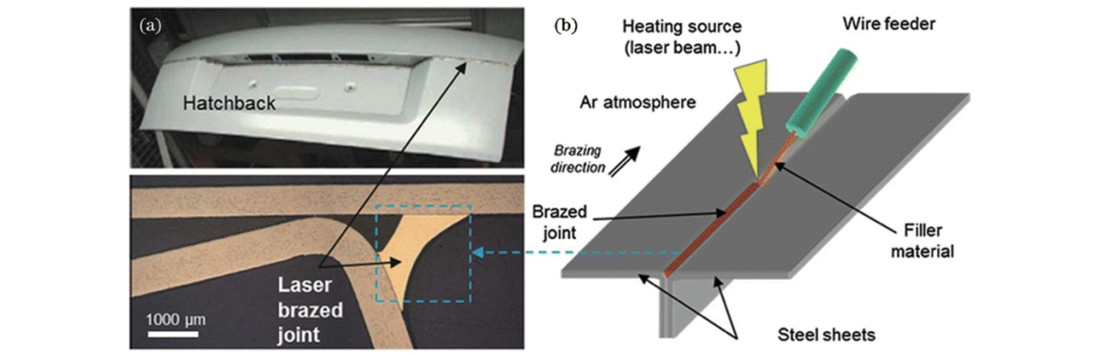

Automotive ahu laser brazing usoro

Usoro brazing laser na-adabere n'ụkpụrụ ndị a: Iji laser dị ka isi iyi ọkụ, ọkụ laser na-elekwasị anya ma gbanye ya n'elu waya ahụ, waya na-agbaze, waya gbazere na-agbadata ma jupụta workpiece ka a ga-agbaze. na mmetụta metallurgical dị ka agbaze na mgbasa na-eme n'etiti ihe brazing na workpiece, si otú a na-esonyere workpiece. N'adịghị ka usoro ịgbado ọkụ laser filler, usoro brazing laser na-agbaze waya naanị ọ bụghị ihe arụrụ arụ ka a ga-agbakọ. Laser brazing nwere ezigbo ịgbado ọkụ kwụsie ike, ma ike tensile nke weld pụta dị ala. Ọgụgụ 3 na-egosi ngwa nke laser brazing usoro na akpakanamde akpa ngalaba mkpuchi ịgbado ọkụ

N'ime usoro ịgbado ọkụ nke akpaaka, a na-ejikarị usoro brazing laser iji weld akụkụ ahụ nke na-adịghị achọ ike nkwonkwo dị elu, dị ka ịgbado ọkụ n'etiti mkpuchi elu na akụkụ gbara ya gburugburu, ịgbado ọkụ n'etiti akụkụ elu na nke ala nke akpa ahụ. mkpuchi nke ngalaba, wdg. The top cover nke VW, Audi na ndị ọzọ na-ajụ na elu-ọgwụgwụ ụdị na-niile na-eji laser brazing usoro.

Isi ntụpọ na nkwonkwo brazed laser nke ahụ ụgbọ ala gụnyere ọnụ ịhịa aka n'ahụ, porosity, nrụrụ weld, wdg, enwere ike belata ntụpọ ahụ site na ịhazi usoro usoro yana iji usoro brazing laser lekwasịrị anya ọtụtụ.

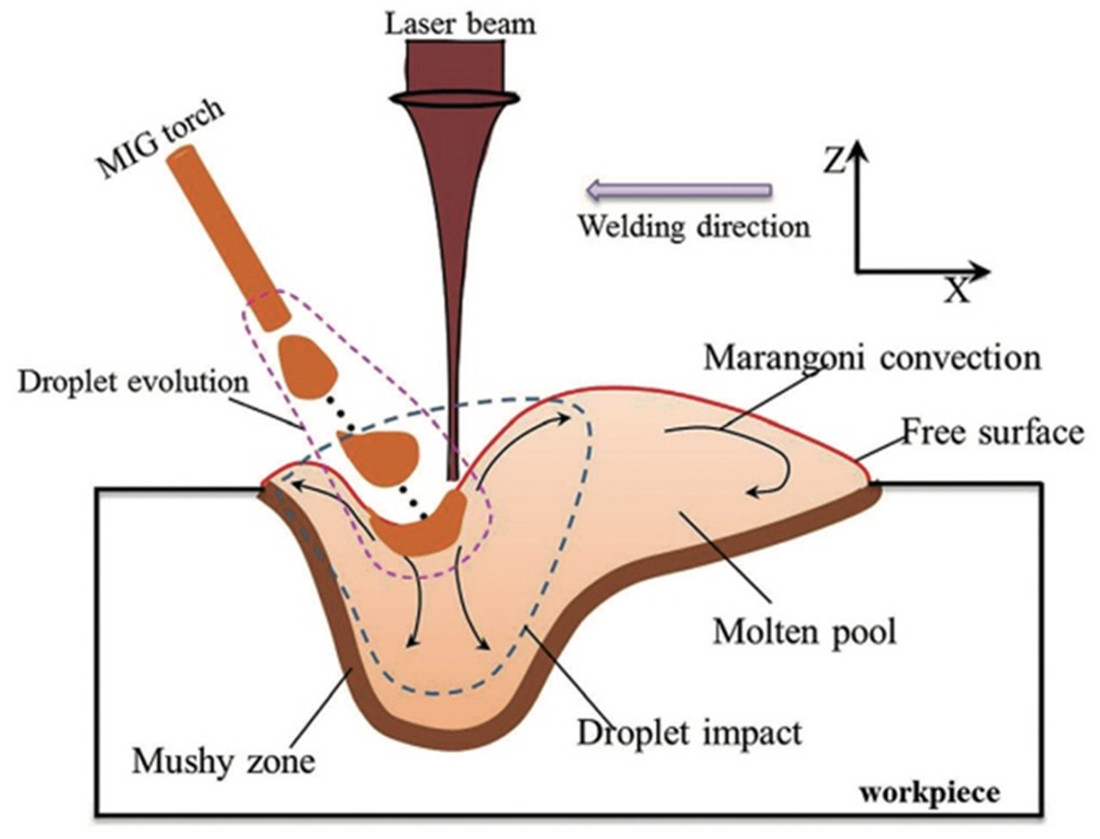

Automotive ahu laser-arc mejupụtara usoro ịgbado ọkụ

Ụkpụrụ nke usoro ịgbado ọkụ laser-arc mejupụtara bụ nke a: a na-eji isi mmiri ọkụ abụọ, laser na arc eme ihe n'otu oge na-eme ihe n'elu ihe a na-eme ka ọ bụrụ welded, na-agbazekwa workpiece na-agbaze ma sie ike na-eme ka ọkpụkpụ weld. Eserese dị n'okpuru na-egosi usoro ịgbado ọkụ laser-arc.

Laser-arc composite welding na-ejikọta uru nke ịgbado ọkụ laser na arc welding: nke mbụ, n'okpuru ọrụ nke isi mmalite okpomọkụ, enwere ike ịbawanye ọsọ ịgbado ọkụ, ntinye ọkụ na-adị ntakịrị, nrụrụ weld dị ntakịrị, na-ejigide njirimara nke ịgbado ọkụ laser. ; nke abụọ, ka mma chịkọta ikike, mgbakọ ọdịiche ndidi ukwuu; nke atọ, ngwa ngwa siri ike nke ọdọ mmiri a wụrụ awụ na-adị nwayọọ, nke na-eme ka ikpochapụ pores, cracks na ntụpọ ịgbado ọkụ ndị ọzọ, melite nhazi na arụmọrụ nke mpaghara okpomọkụ emetụtara nke anọ, n'ihi arc, ọ na-enwe ike ịgbado ọkụ. ihe ndị nwere ihe ngosi dị elu na ịdị elu nke thermal conductivity, nke nwere ọtụtụ ihe eji eme ihe.

Na akpaaka ahu n'ichepụta usoro, laser - arc mejupụtara ịgbado ọkụ usoro bụ tumadi ịgbado ọkụ ozu aluminum alloy components na aluminum alloy - ígwè dissimilar ọla, n'ihi na mgbakọ ọdịiche nke ibu akụkụ nke ịgbado ọkụ, dị ka ụgbọ ala ụzọ akụkụ nke ọnọdụ. ịgbado ọkụ, nke a bụ n'ihi na oghere mgbakọ na-enyere aka laser - arc composite welding bridging performance. Na mgbakwunye, a na-etinyekwa teknụzụ ịgbado ọkụ laser-MIG arc n'akụkụ elu ụlọ nke ahụ Audi.

N'ime usoro ịgbado ọkụ nke akpaaka, ịgbado ọkụ laser-arc mejupụtara nwere uru nke nnabata dị ukwuu ma e jiri ya tụnyere otu ịgbado ọkụ laser, agbanyeghị, ịgbado ọkụ laser-arc chọrọ nleba anya zuru oke nke ọnọdụ ikwu nke laser na arc, paramita ịgbado ọkụ laser, arc. parameters na ihe ndị ọzọ. The okpomọkụ na uka nnyefe omume nke laser-arc ịgbado ọkụ usoro bụ mgbagwoju, karịsịa ike ụkpụrụ nke heterogeneous ihe ịgbado ọkụ na usoro nke IMC ọkpụrụkpụ na anụ ahụ ụkpụrụ bụ ka edoghị anya na-achọkwu ike nke nnyocha.

Ndị ọzọ akpakanamde ahu laser ịgbado ọkụ Filiks

Mgbado ọkụ laser miri emi, ịgbado ọkụ laser, brazing laser na laser-arc composite welding na usoro ịgbado ọkụ ndị ọzọ nwere echiche tozuru oke yana ọtụtụ ngwa bara uru. Ka ihe ndị ụlọ ọrụ ụgbọ ala chọrọ maka ịrụ ọrụ ịgbado ọkụ anụ ahụ na-abawanye na ọchịchọ maka ịgbado ọkụ nke ihe ndị dị iche na n'ichepụta dị fechaa, ịgbado ọkụ laser, ịgbado ọkụ laser, ịgbado ọkụ ọtụtụ laser na ịgbado ọkụ laser enwetala nlebara anya.

Usoro ịgbado ọkụ laser ntụpọ

Laser ntụpọ ịgbado ọkụ bụ ihe elu laser ịgbado ọkụ technology na pụtara ìhè uru nke ngwa ịgbado ọkụ ọsọ na elu ịgbado ọkụ ziri ezi. Ụkpụrụ bụ isi nke ịgbado ọkụ laser ntụpọ bụ ilekwasị anya n'ọkụ laser n'otu akụkụ nke a ga-agbaze, nke mere na metal ahụ na-agbaze ozugbo, na site n'ịgbanwe njupụta laser iji nweta ịgbado ọkụ ọkụ ma ọ bụ mmetụta ịgbado ọkụ miri emi, mgbe laser doo akwụsị ịrụ ọrụ, mmiri mmiri metal refluxes, solidifies na-etolite a nkwonkwo.

E nwere isi ihe abụọ dị iche iche nke laser ntụpọ ịgbado ọkụ: pulsed laser ntụpọ ịgbado ọkụ na-aga n'ihu laser ntụpọ ịgbado ọkụ. The laser doo na pulsed laser ntụpọ ịgbado ọkụ nwere a elu elu ume, ma omume oge dị mkpụmkpụ, na-ejikarị maka ịgbado ọkụ nke ọla ọla dị ka magnesium alloys na aluminum alloys. Na-aga n'ihu laser ntụpọ ịgbado ọkụ, na laser doo nwere a elu nkezi ike na ogologo oge laser edinam, na-akasị eji maka ịgbado ọkụ nke ígwè.

Na akpaaka ahụ ịgbado ọkụ, tụnyere na-eguzogide ntụpọ ịgbado ọkụ, laser ntụpọ ịgbado ọkụ nwere uru nke na-abụghị kọntaktị na onwe haziri ntụpọ ịgbado ọkụ trajectory, nke nwere ike izute ina elu-edu ịgbado ọkụ n'okpuru dị iche iche n'apata oghere nke akpaaka ahu ihe.

Usoro ịgbado ọkụ Laser oscillation

Laser oscillation ịgbado ọkụ bụ ọhụrụ laser ịgbado ọkụ technology na-atụ aro na-adịbeghị anya na enwetawo nlebara anya zuru ebe nile. Ụkpụrụ nke nkà na ụzụ a bụ iji nweta ngwa ngwa, n'usoro na obere oscillation nke laser beam site na ijikọta enyo na-egbuke egbuke n'ime isi ịgbado ọkụ laser, si otú a na-enweta mmetụta nke ịkpali ọkụ mgbe ị na-aga n'ihu n'oge ịgbado ọkụ laser.

Isi trajectories oscillation na usoro ịgbado ọkụ laser oscillation gụnyere: transverse oscillation, longitudinal oscillation, okirikiri oscillation na enweghi ngwụcha. The laser oscillation ịgbado ọkụ usoro nwere ịrịba uru na auto ahu ịgbado ọkụ, dị ka eruba ala nke gbazee ọdọ mmiri na-n'ụzọ dị ịrịba ama site oscillation nke laser doo, otú usoro nwere ike wepụ unfused ntụpọ, nweta ọka ukpụhọde na suppress porosity na ịgbado ọkụ nke. otu akpaaka ahu ihe, na melite nsogbu nke ezughi oke Ịgwakọta dị iche iche ihe na ogbenye n'ibu Njirimara nke weld onuete na ịgbado ọkụ nke dissimilar auto ahu ihe.

Multi-Laser doo usoro ịgbado ọkụ

Ka ọ dị ugbu a, enwere ike iji laser fiber kewaa otu ogwe ọkụ laser n'ime ọtụtụ ogwe ọkụ laser site na iji modul nkewa nkewa nke etinyere na isi ịgbado ọkụ. Multi-Laser beam ịgbado ọkụ bụ nhata n'itinye otutu isi mmalite okpomọkụ na ịgbado ọkụ usoro. Site n'ịgbanwe ike nkesa nke ọkụ ahụ, ọkpụkpụ dị iche iche nwere ike ịrụ ọrụ dị iche iche, dị ka: ogwe nke nwere ike dị elu bụ isi ọkụ, na-ahụ maka ịgbado ọkụ miri emi; sub-beam na obere ume njupụta nwere ike ihicha na preheat elu ihe na-amụba absorption nke laser doo ike site ihe.

Usoro ịgbado ọkụ nke ọtụtụ laser nwere ike imeziwanye omume evaporation nke zinc vepor na omume siri ike nke ọdọ mmiri gbazee n'oge ịgbado ọkụ nke mpempe akwụkwọ nchara galvanized, meziwanye nsogbu ịgbasa ma welie ike ike nke weld seam.

Usoro ịgbado ọkụ nke ụgbọ elu laser

Teknụzụ ịgbado ọkụ nke ụgbọ elu Laser bụ teknụzụ ịgbado ọkụ laser ọhụrụ nwere arụmọrụ ịgbado ọkụ dị elu yana ihe kwụụrụ onwe ya nke trajectory ịgbado ọkụ. Ụkpụrụ bụ isi nke ịgbado ọkụ ụgbọ elu laser bụ na mgbe eriri laser na-eme na enyo X na Y nke enyo nyocha, a na-achịkwa akụkụ nke enyo site na mmemme nwere onwe ya iji nweta ngbanwe nke eriri laser n'akụkụ ọ bụla.

Na omenala, ịgbado ọkụ laser nke ahụ akpaaka na-adabere na robot ịgbado ọkụ iji kwọọ isi ịgbado ọkụ laser maka mmegharị ahụ na-emekọrịta ihe iji nweta mmetụta ịgbado ọkụ. Otú ọ dị, mmegharị nke robọt ịgbado ọkụ ugboro ugboro na-egbochi ịrụ ọrụ nke ọma ịgbado ọkụ n'ihi ọnụ ọgụgụ dị ukwuu nke weld na ogologo ogologo nke welds. N'ụzọ dị iche, laser ụgbọ elu ịgbado ọkụ nwere ike nweta n'ime a ụfọdụ nso site na nnọọ ukpụhọde n'akuku nke reflector. Ya mere, teknụzụ ịgbado ọkụ ụgbọ elu laser nwere ike imeziwanye arụmọrụ ịgbado ọkụ ma nwee atụmanya ngwa ngwa.

Nchịkọta

Site na mmepe nke ụlọ ọrụ ụgbọ ala, ọdịnihu nke teknụzụ ịgbado ọkụ anụ ahụ ga-aga n'ihu na-etolite na usoro ịgbado ọkụ na teknụzụ nwere ọgụgụ isi.

Ahụ akpaaka, ọkachasị ahụ ụgbọ ala ume ọhụrụ, na-etolite na ntụzịaka nke ịdị arọ. Lightweight alloys, mejupụtara ihe na heterogeneous ihe ga-ọzọ n'ọtụtụ ebe na-eji na akpaaka ahu, ot laser ịgbado ọkụ usoro siri ike izute ya ịgbado ọkụ chọrọ, otú elu àgwà na ịrụ ọrụ nke ọma ịgbado ọkụ usoro ga-aghọ ọdịnihu mmepe na-emekarị.

N'ime afọ ndị na-adịbeghị anya, usoro ịgbado ọkụ laser na-apụta, dị ka ịgbado ọkụ laser, ịgbado ọkụ multi-laser, ịgbado ọkụ ụgbọ elu laser, wdg, anọwo n'ịdị mma ịgbado ọkụ na ịgbado ọkụ nke nyocha usoro nyocha mbụ na nyocha usoro. Ọdịnihu kwesịrị ịbụ usoro ịgbado ọkụ laser na-apụta na ihe ahụ dị fechaa, ihe ịgbado ọkụ dị iche iche na ọnọdụ ndị ọzọ jikọtara ọnụ, ihe nrụpụta laser beam swing trajectory design, multi-laser beam energy action usoro na ụgbọ elu ịgbado ọkụ arụmọrụ mma na akụkụ ndị ọzọ nke in- nyocha miri emi iji nyochaa usoro ịgbado ọkụ ahụ nke tozuru oke.

Auto ahu laser ịgbado ọkụ technology a na-miri nke ukwuu integrated na nwere ọgụgụ isi technology, ozugbo mmetụta nke auto body laser ịgbado ọkụ ọnọdụ na nzaghachi akara nke usoro parameters nwere bụrụkwa ọrụ na ịgbado ọkụ àgwà. A na-ejikarị teknụzụ ịgbado ọkụ laser nwere ọgụgụ isi ugbu a maka nhazi trajectory tupu ịgbado ọkụ na nsochi na nyocha ogo ịgbado ọkụ. Domestic na mba ọzọ nnyocha na nchọpụta nke ịgbado ọkụ ntụpọ na adaptive ụkpụrụ nke parameters ka na ya ọhụrụ, na laser ịgbado ọkụ usoro parameters adaptive akara nkà na ụzụ e tinye n'ọrụ na akpaaka ahu n'ichepụta.

Ya mere, maka ngwa nke laser ịgbado ọkụ technology na akpaaka ahu ịgbado ọkụ usoro e ji mara, ga-eme n'ọdịnihu ga-mepụtara na elu multi-sensọ isi laser ịgbado ọkụ nwere ọgụgụ isi usoro na elu-ọsọ elu-nkenke ịgbado ọkụ robot akara usoro iji hụ na laser ịgbado ọkụ. nkà na ụzụ nwere ọgụgụ isi na ozugbo na izi ezi nke njikọ ọ bụla, site na njikọ "atụmatụ ịgbado ọkụ trajectory atụmatụ - welding parameters adaptive control post-welding quality online Inspection" njikọ, iji hụ na elu. àgwà na nhazi nhazi.

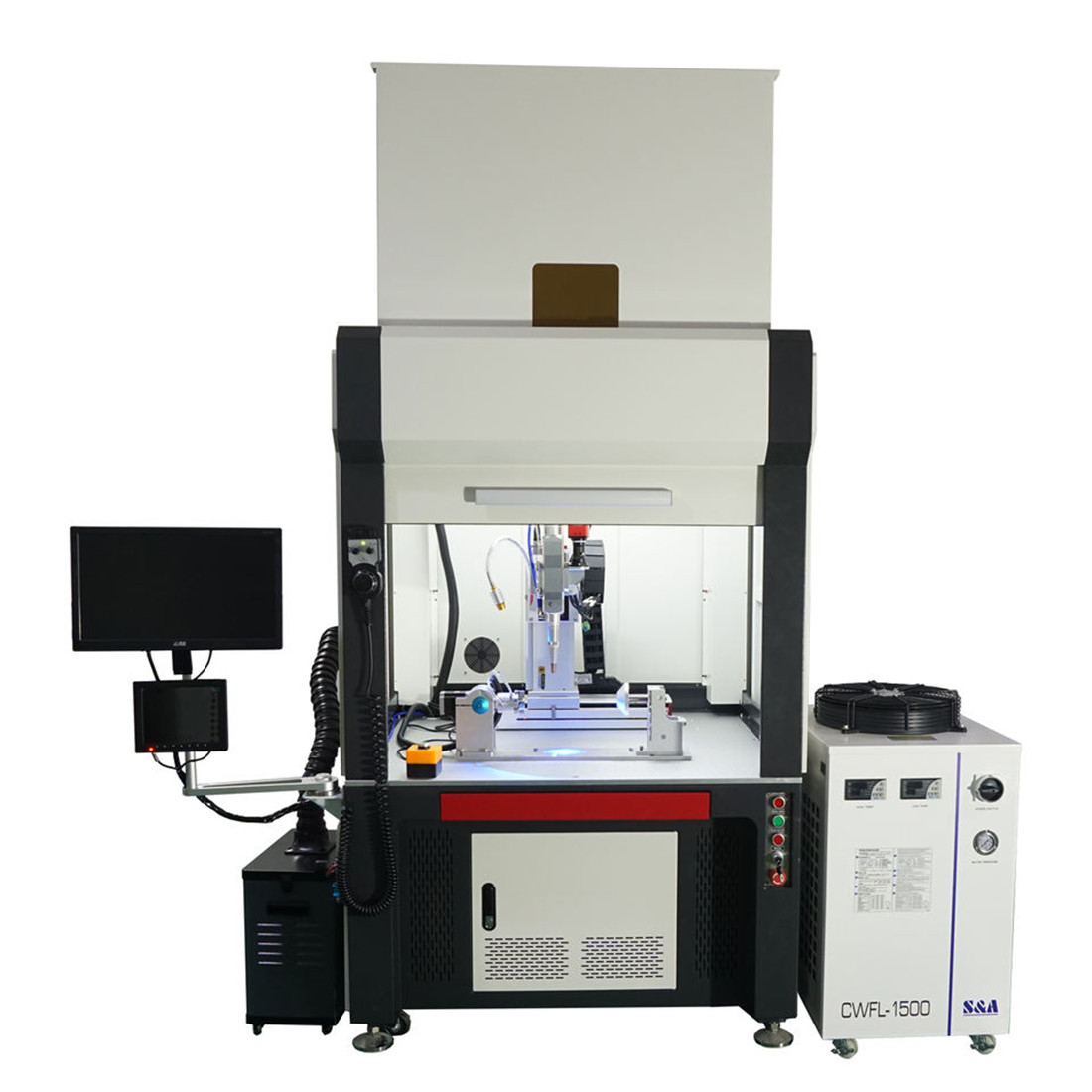

Maven laser automation ụlọ ọrụ na-elekwasị anya na ụlọ ọrụ laser maka afọ 14, anyị na-ahụ maka ịgbado ọkụ laser, anyị nwere igwe na-agbado ọkụ laser, Tebụl Automatic Laser Welding Machine, Igwe ịgbado ọkụ Laser Handheld, na mgbakwunye, anyị nwekwara igwe ịgbado ọkụ laser, igwe ịkpụ laser. na laser marking machine machine, anyị nwere ọtụtụ ihe ngwọta ịgbado ọkụ laser, ọ bụrụ na ị nwere mmasị ị nwere ike ịkpọtụrụ anyị mgbe niile.

Oge nzipu: Dec-09-2022